Standard Stock Definition Continuous Manufacturing Definition

Process manufacturing is a production method that creates goods by combining supplies, ingredients or raw materials using a formula or recipe. It is frequently used in industries that produce bulk quantities of goods, such as food, beverages, refined oil, gasoline, pharmaceuticals, chemicals and plastics.

The production process often requires a thermal or chemical conversion, such as with heat, time or pressure. As a result, a product created through process manufacturing cannot be disassembled into its constituent parts. For example, once it is produced, a soft drink cannot be broken down into its separate ingredients.

Process manufacturing relies on the flow of sequential steps, with the completion of one step leading to the start of the next step. Process manufacturers often rely on tracing and scheduling tools and software to maintain peak operational efficiency.

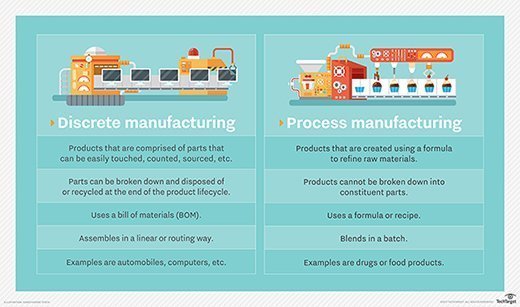

Process manufacturing vs. discrete manufacturing

Process manufacturing is the exact opposite of discrete manufacturing. Whereas process manufacturing follows recipes or formulas and creates products that cannot be broken down at the end of the production cycle, discrete manufacturing uses a bill of materials (BOM) and follows instructions to create finished, assembled goods. At the end of the discrete manufacturing process, the final product can be broken down into its distinct parts, which can sometimes be recycled. Goods produced through discrete manufacturing include automobiles, computers and some toys.

Discrete manufacturing can be associated with:

- assembly lines

- fabrication

- standard parts and components

- bill of materials

- identification of parts by numbers

- measured by each part or piece

While process manufacturing can be associated with:

- recipes and formulas

- mixes and blends

- variable ingredients

- identification of parts by attributes

- measurements of weight or volume

Process manufacturing can be considered more complex than discrete manufacturing since it involves transforming individual raw materials and process inputs into a final product. However, it is also less defect-oriented and experiences fewer interruptions and improved quality control (QC) throughout the production process.

Types of manufacturing processes

Within the manufacturing industry, various processes are used -- in addition to process and discrete manufacturing -- to determine how a company will produce its products. The three other common manufacturing processes include:

- repetitive manufacturing (REM)

- job shop manufacturing

- 3-D printing

Repetitive manufacturing is used for repeated production that is committed to a specific production rate. The process is made up of dedicated production lines that continuously create the same product, or collection of products, year-round. Setup requirements are minimal and there is little changeover, so operation speeds can be adjusted to meet customer demands and requirements.

Job shop manufacturing uses production areas instead of assembly or production lines and focuses on producing smaller amounts of custom products, including made-to-order (MTO) and made-to-stock (MTS) goods. If customer demand increases, then the operation adapts and becomes a discrete process with selected manual operations being replaced by automated equipment.

3D printing -- also known as additive manufacturing -- is the newest manufacturing process. Although it was first conceived in the 1980s, it has only recently been introduced into production cycles. The 3D printing process produces goods from various composites and materials, building layers to create a three-dimensional solid object from a digital model.

Process manufacturing can also be split into two different production methods: continuous process manufacturing and batch process manufacturing.

Continuous process manufacturing is similar to repetitive manufacturing in the sense that it never ends -- it produces the same product or collection of products year-round. On the other hand, batch process manufacturing depends on customer demand. One batch -- or specific quantity of goods produced during a time frame -- may be enough to satisfy the demand. When a batch is completed, the equipment is cleaned and prepared to produce the next batch when necessary.

Process manufacturing software

Because it's a complex and often highly specialized activity, most manufacturers use enterprise resource planning (ERP) software systems that have specific functions for process manufacturing.

Various enterprise software vendors produce these systems, including:

- SAP

- Oracle

- Microsoft

- Infor

- IFS

- Sage

- IQMS

- Plex Systems

- Syspro

Each vendor may sell a variety of systems that are targeted toward enterprises of various sizes, from small and medium-sized businesses (SMBs) to large enterprises.

Originally, most ERP systems for process manufacturing ran on premises. Recently, the switch has been made to deploying most software in the cloud or in hybrid implementations.

Examples of process manufacturing

Some of the top process manufacturing markets include:

- food and beverage

- oil and gas

- pharmaceuticals

- personal care and cosmetics

- plastics

- metals

Beer brewing is one example of process manufacturing in the food and beverage industry. Key ingredients in beer making include grains, malt, hops, yeast and sugar; various recipes are available to guide the process. The basic steps include, first, steeping the grains in boiling water, then the adding malt along with specific quantities of hops -- depending on the type of beer being brewed -- and sugar. This mixture creates the wort, or the liquid that contains the sugars that will be fermented by the yeast to produce alcohol. Once the wort has been created, it is added to water with yeast and left to ferment for an extended period. Once the fermentation is complete, the beer can be bottled; this end product cannot be broken down into its constituent parts.

Hand lotions are an example of a product created through process manufacturing for the personal care and cosmetics industry. Much like beer brewing, hand lotion production involves mixing specific amounts of process inputs to create a complete compound that cannot be broken apart at the end.

This was last updated in February 2020

Continue Reading About process manufacturing

- Discover the best ERP software for your organization

- Why craft beer makers are tapping into ERP for craft brewery software

- 3 ways tech will change manufacturing in 2020

- How can AI improve production planning in manufacturing?

- What software features are key for process manufacturing ERP?

Dig Deeper on Supply chain and manufacturing

-

Keeping pace with different types of manufacturing processes

-

traceability

-

Discrete vs. process manufacturing: Choosing ERP

-

10 ERP software choices for process manufacturing

Source: https://www.techtarget.com/searcherp/definition/process-manufacturing

0 Response to "Standard Stock Definition Continuous Manufacturing Definition"

Enregistrer un commentaire