Clock Stopped at 12 Then Started Again

How to Set a Quartz Clock That Won't Work

Eugene is a qualified control/instrumentation engineer Bsc (Eng) and has worked equally a programmer of electronics & software for SCADA systems.

Typical battery quartz electronic wall clock.

© Eugene Brennan

Cleaning Battery Clocks

Once upon a fourth dimension most of our clocks were air current-up devices, and then we transitioned to electrical clocks that plugged into a mains outlet. Present, many clocks are battery-powered by a single AA cell. The enemy of all clocks though is dust and grime that tin can easily seize up the cogs and stop the mechanism from working. In this guide, I show you which parts you lot can try cleaning to get your clock working once more.

Analog and Digital Clocks

The clock I'm fixing here has an analog display. However the electronics that drives the brandish is digital and uses an oscillator and counter flake for frequency division. To understand the somewhat disruptive divergence betwixt analog and digital which are words that tin can mean different things depending on context, see my article "Analog vs Digital Signals and Displays — What'south the Difference".

How Does a Quartz Clock Work?

The mechanism (besides called the movement) or working parts in a quartz battery clock is a fleck simpler than in a traditional wind-up clock.

At the centre of the clock is a quartz oscillator, which generates a pulse every 2d. An oscillator is a device that does something regularly, similar a pendulum that swings back and forth, a tuning fork vibrating, a string on a guitar or the air in an organ piping. All these are mechanical oscillators, simply there are likewise electronic oscillators.

An electronic oscillator generates a voltage signal that repeats itself at a set up frequency. In the case of the oscillator in a clock, this runs at several g hertz or cycles per second. An electronic component chosen a quartz crystal sets the frequency of the oscillator to well-nigh 32768 Hz with a high degree of accuracy. The frequency is divided down and reduced then that information technology eventually becomes 1Hz or 1 bicycle per second. The output of the oscillator drives an electromagnet that acts on a tiny magnetic rotor, flipping it one-half a turn every second. The rotor has gear teeth that mesh with a train of other gear wheels and this eventually turns the hands of the clock.

The good matter virtually electronic quartz oscillators is that their frequency is very stable and dissimilar mechanical clockwork, doesn't change much with temperature, humidity or other ambience conditions. This means that battery clocks keep good time and don't gain or lose minutes like a wind-up clock as the spring unwinds or temperature changes.

Why Practise Clocks Stop?

- Loose or dirty battery connections

- Low battery

- Bombardment pips not long enough

- Grime accumulating in the mechanism causing excessive friction

Kickoff Steps: What to Try if a Clock Doesn't Piece of work

- Change the bombardment. Information technology may merely exist flat. You tin can check battery condition with a universal battery tester like this one suitable for 1.5 volt AA, AAA, C and D cells and also minor, square 9 volt "PP3" (MN1604) manner batteries

- Clean the connections and battery terminals with rubbing alcohol (which is either isopropyl alcohol (IPA) or ethanol) on a cotton wool bud. The springy electric strips tin besides go oxidised as can the ends of the batteries. This oxidisation sometimes appears equally a grey or light-green coating. You lot can utilize fine wire wool to remove information technology. If the bombardment has leaked and left a white deposit (potassium hydroxide from alkaline batteries), yous can neutralise this first by rubbing with vinegar.

- Cheque the bombardment terminals: Sometimes the terminal pips on batteries can be a little short. Try slightly bending the positive terminal strip in the clock slightly. Caution! These can snap if you curve also much.

- Check the hands: Make the sure the clock hands aren't rubbing against the clear cover over the face of the clock.

Universal bombardment checker suitable for AA, AAA, C, D and MN1604 (PP3) batteries.

© Eugene Brennan

Bombardment connections can be cleaned with isopropyl alcohol (IPA), likewise called rubbing alcohol.

© Eugene Brennan

Clean contacts with IPA.

© Eugene Brennan

Sometimes batteries tin have brusk positive terminal pips.

© Eugene Brennan

Attempt slightly bending the springy terminals if they don't make contact. Don't overbend.

© Eugene Brennan

Next Steps: If the Clock Still Won't Run

If the clock still won't run, the cogs inside may have crud on the teeth or axles. Even though in that location's a encompass on the mechanism compartment, in humid, dirty conditions (e.g., in a bathroom) grit and mildew can manage to get in. So yous need to do some cleaning. The solenoid in the clock simply produces a tiny corporeality of torque or twisting strength to plough the little rotor. Whatsoever grime on the pins of this rotor can produce plenty friction to terminate it from turning.

Scroll to Keep

Read More than From Dengarden

How to Clean the Clock Mechanism

- Remove the cover over the mechanism. This differs from clock to clock. There may be lugs on the mechanism compartment that appoint with the comprehend. If this is the case, push them gently aside with the blade of a screwdriver. Alternatively there may be pins that push into the cover like in the photo below. I was able to push into the hairline gap betwixt the compartment and cover with a small screwdriver and prise upwards the encompass.

- Remove the rotor from between the jaws of the solenoid and the offset couple of gears. These should simply lift out without any difficulty. Friction affecting these gears is nearly probable to end a clock because further down the gear train, there'll be more torque to overcome it. Take a photo before disassembling so you can put everything back together.

- I take found that article of furniture smooth helps to make clean and lubricate the tips of the shafts of the nylon gears where they sit into the case and cover. Spray some polish on a tissue or cotton bud and dab it onto shaft ends and teeth and wipe off the excess.

- Remove whatever obvious dust or fluff in the move.

- If you remove some of the gears, the hands of the clock may fall off, so you may need to remove the articulate faceplate to supercede them.

To become at the mechanism, you need to remove the comprehend on the compartment that holds the gears and electronics.

© Eugene Brennan

Within the clock, an electromagnet moves the little blueish magnetic rotor half a turn every 2nd. This turns the other gears.

© Eugene Brennan

This tiny rotor magnet is well-nigh 3/viii" or 10mm long. Clean the 2 ends of shaft pins to reduce friction.

© Eugene Brennan

You can clean and lubricate the tiny shafts of the gears with piece of furniture smooth.

© Eugene Brennan

You can detach the lugs of the front cover of some clocks past pushing down with your fingers and pulling out at the same time.

.....alternatively push sideways on the lugs and then push downward to remove the faceplate of the clock if you demand to replace the mechanism or hands.

© Eugene Brennan

More Possible Fixes

- Check the voltage on the electromagnet: This should modify polarity every second.

- Reflow the solder: If you lot have a soldering iron, you tin reflow the solder on the joints on the PCB. Sometimes a dry solder joint can foreclose the circuit from working or make it stop working intermittently.

- Check the metal strips: On some clocks, the excursion board presses against strips of metallic that supply power from the bombardment. These strips are springy and press on tinned pads on the PCB. In a bathroom, steam can cause corrosion at these points of contact. Remove the PCB and clean the pads and bound contacts with IPA and fine wire wool.

- Check the magnetic rotor beam: The axle of the magnetic rotor can tarnish if it's made of brass, making it rough and increasing friction, causing information technology to stick. More expensive clocks and watches accept jewelled bearings (e.g., rubies) in which the tiny axles of the cogs rotate, however cheap quartz clock movements just have a nylon plate into which all the axles of the cogs fit. You can try adding a tiny drop of oil, (less than the size of the head of a pin) using the tip of a pivot or a pointed awl to the signal where the rotor axle fits into this plate.

Reflow solder on the joints.

© Eugene Brennan

Use the tip of an awl or pin to use a tiny drop of oil to the bearing.

© Eugene Brennan

If the Clock Still Won't Start, Replace the Machinery

It turned out that the electronics of my clock in the photos above was faulty. You can buy a replacement motility like this one on Amazon. This production has bones manifestly hands.

Mechanisms are somewhat non-standard, so you'll demand to cheque that the hands are the correct size and volition adapt the style of your clock. Alternatively, if they are manifestly rectangular types, y'all demand to check that they tin can be cut and shortened. The threaded piece that fits into the hole in the face of the clock sometimes differ in diameter and length. This should be long enough that whatsoever rubber washers to stop the mechanism turning and bracket hooks for fixing to a wall can be replaced with the piece projecting sufficiently to fix information technology in identify with the retaining ring. Diameter isn't equally critical, but it should exist small enough then it fits through the hole. If it's too pocket-size, it's a niggling more tricky to keep the mechanism centered properly.

You tin buy replacement mechanisms for a few dollars.

© Eugene Brennan

© Eugene Brennan

Attach the retaining band for the clock movement. Don't excessively tighten it every bit it can deform the insides of the movement.

© Eugene Brennan

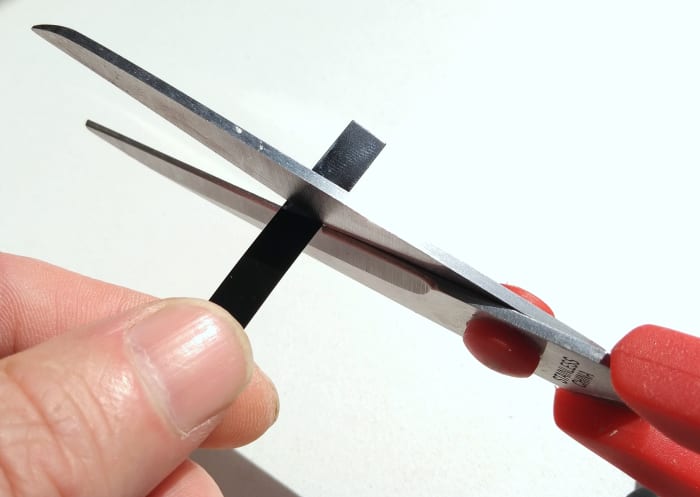

You may demand to shorten easily. You can probably use a sharp scissors.

© Eugene Brennan

Supplant both the hour, infinitesimal and second mitt (if supplied) and point them all to 12 o'clock. Then set the time after replacing the bombardment.

© Eugene Brennan

Using Flat AA Batteries

When a gadget indicates that the batteries are flat, this is often because electronics or software detects that the voltage is below a threshold level sufficient to run the device. This happens with high-power devices that need a minimum voltage to operate. However the energy remaining is often acceptable to run battery clocks for upward to six months.

References

Wikipedia: Quartz Clock

This content is accurate and truthful to the best of the writer's cognition and is not meant to substitute for formal and individualized advice from a qualified professional.

© 2020 Eugene Brennan

Related Manufactures

Source: https://dengarden.com/misc/How-to-Fix-a-Quartz-Digital-Clock-That-Wont-Work

0 Response to "Clock Stopped at 12 Then Started Again"

Enregistrer un commentaire